Cutting straight lines with an angle grinder might seem tricky at first, but with the right approach, you can achieve clean, precise cuts every time. Whether you’re working on metal, tile, or wood, mastering this skill will save you time, reduce frustration, and make your projects look professional.

In this guide, you’ll discover simple tips and tricks that will help you take control of your angle grinder and cut straight with confidence. Ready to transform your cutting game? Let’s dive in and get those perfect straight cuts!

Choosing The Right Disc

Choosing the right disc is key to cutting straight with an angle grinder. The disc affects the cut’s precision and smoothness. A wrong disc can cause rough edges and uneven lines. Select a disc that matches your material and cutting needs. This ensures cleaner, straighter cuts every time.

Types Of Cutting Discs

Cutting discs come in various types for different materials. Thin discs are perfect for metal cutting. They reduce friction and help make straight cuts easily. Diamond discs work best for hard materials like tile or concrete. They last longer and cut smoothly. Abrasive discs suit general-purpose cutting but wear out faster. Using the correct type improves accuracy and safety.

Disc Size And Material

Disc size impacts control and cut quality. Smaller discs offer better control for fine, straight cuts. Larger discs cut faster but are harder to guide. Choose a disc size that fits your grinder and project. The disc’s material also matters. Aluminum oxide discs cut metal well. Silicon carbide suits stone and tile. Matching disc material to your workpiece keeps cuts clean and precise.

Credit: www.homemadetools.net

Preparing Your Workspace

Preparing your workspace is the first step to cutting straight with an angle grinder. A clean and organized area helps you focus and work safely. It also makes your cuts more accurate. Proper setup avoids accidents and damage to your materials.

Securing The Workpiece

Hold your workpiece firmly to stop it from moving. Use clamps or a vise to fix it in place. A steady workpiece lets you cut with more control and precision. Make sure the piece is stable before you start cutting.

Clearing The Cutting Area

Remove any objects near your cutting line. Clear dust, tools, and debris that can get in your way. A clean area gives you a better view of the cut. It also prevents accidents caused by slipping or tripping.

Marking The Cut Line

Marking the cut line correctly is the first step to making a straight cut with an angle grinder. A clear, visible line guides the tool and helps avoid mistakes. Taking time to mark accurately saves effort and material. Use simple tools and techniques to ensure the line is straight and easy to follow.

Using Straightedges And Guides

Use a straightedge or ruler to draw the cut line. Place it firmly on the material. Hold it steady to prevent slipping. Draw the line with a pencil or marker that shows clearly on the surface. For longer cuts, clamps can hold the straightedge in place. This keeps the line perfectly straight and stable while cutting.

Scoring The Line For Accuracy

Scoring means making a shallow groove along the marked line. Use a utility knife or the angle grinder with a light touch. This groove acts as a guide for the cutting wheel. It helps the grinder stay on track and prevents the blade from wandering. Scoring improves the cut’s precision and reduces the chance of errors.

Angle Grinder Setup

Setting up your angle grinder correctly is key to cutting straight lines. A well-prepared tool helps you work safely and achieve accurate results. Take time to adjust speed and install the right disc. These steps make the cutting process smoother and more precise.

Adjusting Speed And Settings

Check your angle grinder’s speed settings before starting. Use a slower speed for thin or delicate materials. Higher speeds work better for thick metals and hard surfaces. Adjust the speed dial or switch to match the material you cut. This control helps prevent mistakes and keeps the disc from overheating.

Installing The Disc Correctly

Choose the right disc for the job, such as a cutting or grinding disc. Place the disc on the spindle carefully. Make sure it fits snugly and is centered. Tighten the locking nut firmly but avoid over-tightening. A loose or tilted disc can cause uneven cuts and be dangerous. Always double-check the disc before turning on the grinder.

Cutting Techniques

Cutting straight with an angle grinder requires good technique. The way you move the grinder affects the cut quality. Proper cutting methods reduce mistakes and improve accuracy. Focus on smooth, controlled movements to guide the blade.

Choosing the right motion and pressure helps maintain control. These two factors work together for clean, straight cuts. Understanding how to slide or rock the grinder changes the cut path. Consistent pressure keeps the blade steady on the line.

Sliding Vs Rocking Motion

The sliding motion means moving the grinder forward steadily along the cut line. This keeps the blade flat against the surface. It works best on thin or straight materials. The blade glides smoothly without forcing it.

The rocking motion involves tilting the grinder slightly from side to side. It helps start the cut or cut curves. This motion gives more control over the blade angle. Use rocking for thick or uneven materials to avoid binding.

Both motions have benefits. Use sliding for long straight lines. Use rocking for detailed or rough cuts. Combining these motions can improve your cutting accuracy.

Maintaining Consistent Pressure

Apply steady pressure to keep the blade on track. Too much force can make the blade wander. Too little pressure slows the cut and increases wear. Let the grinder’s speed do the work.

Hold the tool firmly but relaxed. This helps reduce vibration and keeps the cut line clear. Move the grinder at a steady pace. Avoid pushing or pulling abruptly to prevent mistakes.

Consistent pressure also extends the life of the cutting disc. It reduces heat buildup and blade damage. Practice gentle, even force for best results.

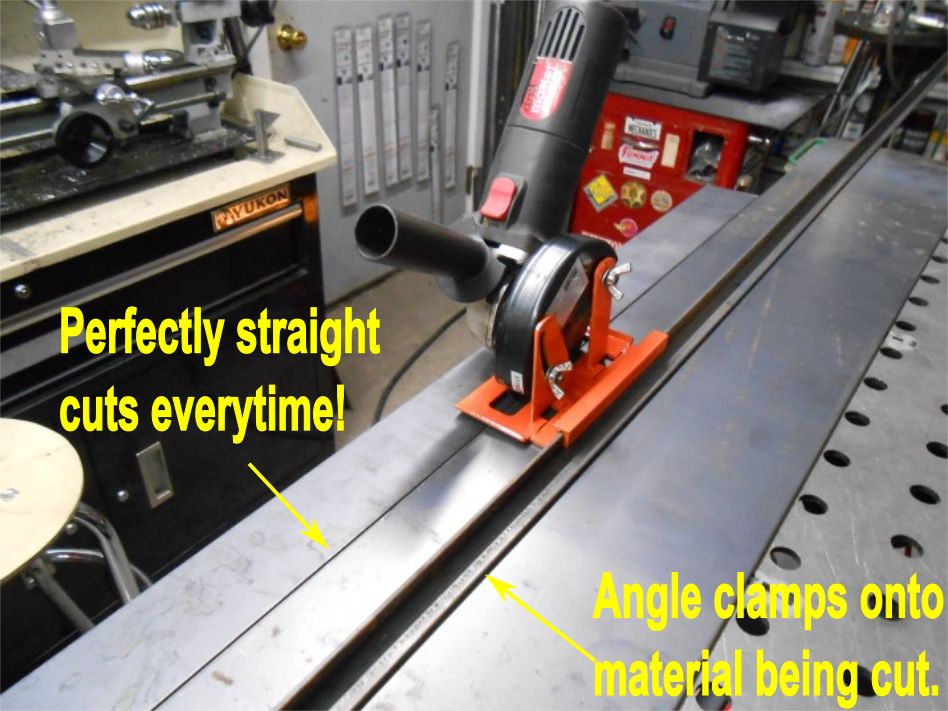

Using Cutting Jigs And Guides

Cutting straight lines with an angle grinder can be tough without the right tools. Cutting jigs and guides help keep the grinder steady and the cut accurate. These tools reduce mistakes and save time. Using jigs or guides is key for clean, straight cuts, especially on metal or tile.

Diy Sliding Jigs

Sliding jigs are simple tools you can make at home. They hold the angle grinder and guide it along a straight path. Use wood or metal strips as rails. Attach the grinder to a base that slides smoothly along these rails. This setup helps maintain a steady line and controls the depth of the cut.

DIY sliding jigs fit many projects and are cost-effective. Adjust the jig size to match your workpiece. Adding handles or clamps improves control and safety. These jigs also help beginners cut straighter without needing advanced skills.

Commercial Straight Cutting Guides

Commercial straight cutting guides offer precision and ease of use. They come ready to attach to your angle grinder or work surface. These guides often have adjustable clamps to fit different materials. The rails are made from metal or hard plastic for durability.

Many commercial guides include measurement marks for quick setups. They help you make long, straight cuts effortlessly. These guides are ideal for professional use or frequent cutting tasks. Investing in one can improve your work quality and speed significantly.

Safety Tips

Cutting straight with an angle grinder requires attention to safety. The tool spins at high speed and can cause serious injury. Taking proper safety steps protects you and others nearby. Use the right gear and handle the grinder carefully.

Protective Gear

Always wear safety glasses or a face shield. This protects your eyes from sparks and flying debris. Use ear protection to guard against loud noise. Wear gloves to keep your hands safe from cuts and heat. Choose long sleeves and sturdy pants to protect your skin. Closed-toe shoes are a must to shield your feet. Avoid loose clothing or jewelry that can get caught in the grinder.

Safe Handling Practices

Hold the angle grinder with both hands firmly. Keep a steady grip to control the tool well. Make sure the workpiece is securely clamped or fixed in place. Never cut freehand without support. Keep the power cord away from the cutting area. Check that the grinding disc is in good condition before use. Allow the grinder to reach full speed before starting the cut. Do not force the tool; let it cut at its own pace. Always stand to the side, not directly behind the grinder. Turn off the tool and wait for the disc to stop before setting it down.

Common Mistakes To Avoid

Cutting straight with an angle grinder can be tricky. Many beginners make simple errors that affect the cut quality. Avoiding these mistakes helps you achieve clean, straight cuts every time. Below are two common errors to watch out for.

Forcing The Grinder

Forcing the grinder slows the blade and damages the disc. The tool should cut smoothly with light pressure. Let the disc do the work. Pushing too hard causes uneven cuts and can lead to accidents. Keep a steady hand and guide the grinder gently along the line.

Ignoring Disc Wear

A worn disc cuts poorly and risks breaking. Check the disc before starting any job. Replace it if it shows cracks, chips, or significant wear. Using a fresh disc keeps the cut clean and safe. Never ignore the condition of your cutting disc for better results.

Finishing The Cut

Finishing the cut is a key step to achieve a clean and professional result. After cutting with an angle grinder, the edges often need extra work to make them smooth and straight. This step helps prevent injuries and improves the look of your project.

Smoothing Edges

Use a flap disc or grinding wheel to smooth rough edges. Move the grinder gently along the cut line. Avoid pressing too hard to prevent uneven surfaces. Take your time to remove burrs and sharp spots. Wear safety gloves to protect your hands during this process.

Checking For Straightness

Check the cut line using a ruler or straightedge. Place it along the edge to see if the cut is even. Look for any bumps or curves that need correction. Mark spots that require more grinding. Repeat smoothing until the edge is perfectly straight and smooth.

Credit: www.youtube.com

Credit: amastone.com

Frequently Asked Questions

How To Cut Precisely With An Angle Grinder?

Mark a clear guide line and secure the workpiece firmly. Use a cutting guide or straight edge for accuracy. Hold the grinder steadily, start the cut slowly, and follow the line with smooth, controlled movements. Maintain consistent pressure and let the blade do the work.

Should You Push Or Pull An Angle Grinder?

Push or pull an angle grinder using a steady sliding motion along the cut line. Let the wheel pull itself through the material. Avoid forcing it straight down to ensure smoother, safer, and more precise cuts.

How To Cut Something Perfectly Straight?

Mark a clear straight line using a ruler or guide. Secure the material firmly. Use a sharp blade or cutting tool, and cut steadily along the mark. Keep your hand steady and move the tool smoothly. Use clamps or a cutting jig for more accuracy.

Which Way To Cut With An Angle Grinder?

Cut with an angle grinder by aligning the disc’s rotation arrow with the grinder’s spin. Use a steady, controlled motion along the cut line. Guide the grinder smoothly without forcing it to ensure clean, straight cuts.

Conclusion

Cutting straight with an angle grinder takes practice and patience. Use guides or clamps to keep your line steady. Move the grinder smoothly and avoid forcing the tool. Keep your eyes on the cutting line at all times. Always wear safety gear to protect yourself during work.

With these tips, your cuts will become cleaner and more accurate. Remember, steady hands and the right technique matter most. Try these steps on small projects first to build confidence. Soon, straight cuts will feel natural and easy to achieve.