Cutting off a bolt might seem like a tough job, but with the right tools and steps, you can do it quickly and safely. If you’ve ever struggled to remove a bolt or needed to shorten one, an angle grinder is your best friend.

But how do you use it without ruining the threads or making a messy cut? In this guide, you’ll learn exactly how to cut off a bolt with an angle grinder, step-by-step. You’ll discover simple tips to protect the bolt’s threads, keep your workspace safe, and get a clean, professional cut every time.

Keep reading—your next bolt-cutting project just got a whole lot easier!

Credit: binictools.com

Preparing The Bolt

Secure the bolt firmly before cutting to prevent movement. Clear any rust or debris from the cutting area for a smooth cut. Use protective gear and ensure the angle grinder’s cutting disc is suitable for metal.

Preparing the bolt properly is key to a clean cut. It helps protect the threads and keeps the bolt steady. This step makes cutting easier and safer. Follow these methods to prepare the bolt before using an angle grinder.

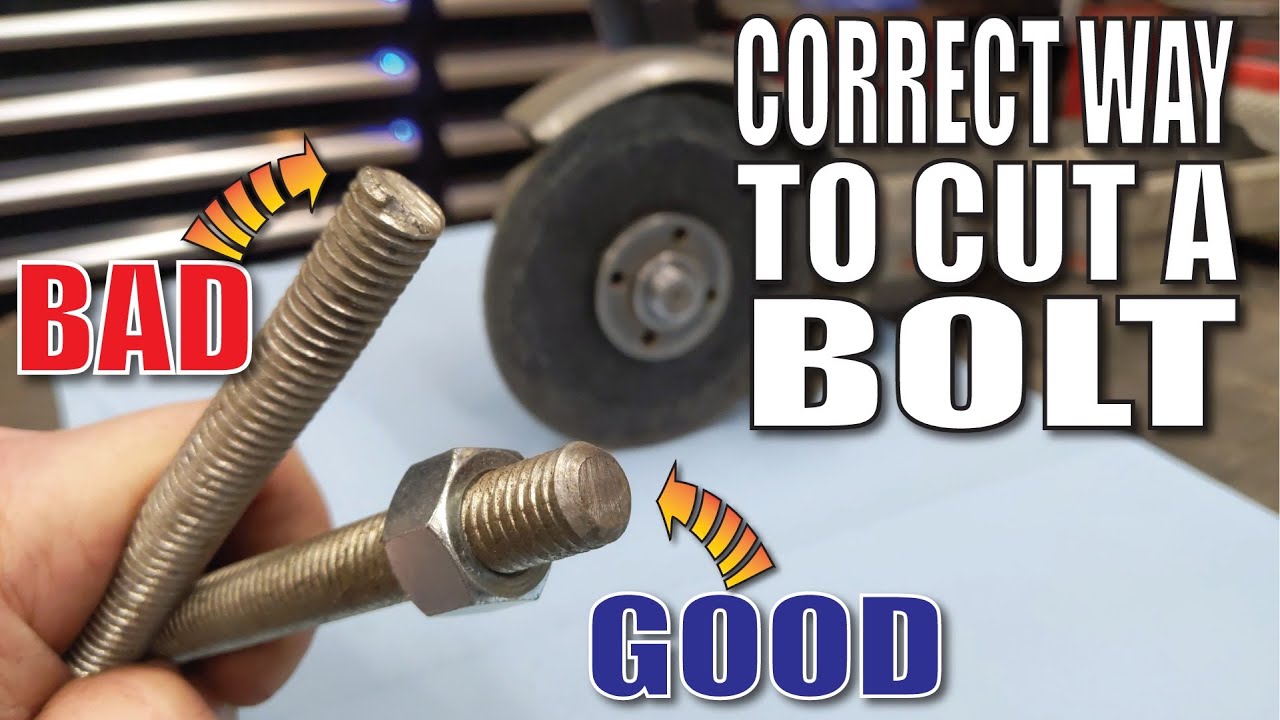

Securing With Nuts

Place two nuts tightly on the bolt, one against the other. This locks them in place and stops the bolt from turning. Tighten the nuts with a wrench to hold the bolt firmly. The nuts protect the threads from damage during cutting. After cutting, unscrew the nuts to check the threads.

Using A Vise Or Clamp

Use a vise or clamp to hold the bolt steady. Position the bolt so the cutting spot is clear and accessible. Tighten the vise or clamp securely to stop the bolt from moving. This keeps your hands free and reduces risk of injury. Always check the bolt is stable before starting the cut.

Credit: www.youtube.com

Choosing The Right Tool

Choosing the right tool for cutting bolts affects the job’s ease and quality. Each tool offers different benefits depending on bolt size and material. Picking the proper tool helps you work faster and safer. It also protects the bolt threads if you need to reuse them. Here are some common tools to consider for cutting bolts.

Angle Grinder With Cutoff Wheel

An angle grinder with a cutoff wheel cuts bolts quickly. It handles various bolt sizes and metals well. This tool spins a thin disc at high speed to slice through metal. Use steady pressure and keep the wheel straight to ensure a clean cut. Wear safety gear to protect from sparks and metal shards.

Oscillating Multi-tool

The oscillating multi-tool uses a small, vibrating blade to cut bolts. It works best for smaller bolts or tight spaces. This tool offers precise control and less risk of damaging threads. It’s quieter and creates less dust than an angle grinder. Choose the right blade for metal cutting.

Hacksaw For Precision

A hacksaw provides precise cuts on bolts, especially small or delicate ones. It needs more effort but keeps the bolt threads intact. Hacksaws are affordable and easy to use without power. Use a fine-toothed blade and steady strokes for the best results.

Wire Cutters And Strippers

Wire cutters and strippers work well on very small bolts or wire-like fasteners. They offer quick cuts with minimal damage. These tools are hand-powered and easy to handle. Avoid using them on thick or hardened bolts to prevent damage.

Bandsaw For Hard Bolts

A bandsaw cuts through hard or thick bolts with ease. It uses a continuous blade to provide smooth, even cuts. This tool is ideal for heavy-duty jobs or large bolts. Set the proper speed and blade type for metal cutting to avoid overheating.

Cutting Techniques

Cutting techniques are key to successfully cutting off a bolt with an angle grinder. The right method makes the task easier and safer. Different tools and setups suit different bolt sizes and materials. Knowing these techniques helps achieve clean cuts and protects the bolt threads.

Here are some common cutting techniques using power tools, hand tools, and jigs for stability.

Power Tool Cutting Methods

Angle grinders are fast and efficient for cutting bolts. Use a thin cutting disc designed for metal. Hold the grinder steady and cut at a right angle to the bolt. Avoid twisting the tool to prevent damage.

Oscillating tools with metal cutting blades offer more control. They work well for small bolts or tight spaces. Bandsaws cut hard bolts cleanly but require more setup.

Hand Tool Cutting Methods

Hacksaws are simple and precise for cutting bolts by hand. Choose a blade with fine teeth for metal. Saw slowly to keep the cut straight. Wire cutters can cut small bolts or soft metals quickly.

Bolt cutters provide strong leverage for thick bolts. They require less effort but need space to open the jaws fully.

Using Jigs For Stability

Jigs hold the bolt firmly while cutting. This prevents movement and improves cut accuracy. A bench vise is the most common jig to secure bolts.

Clamping the bolt with two nuts jammed together also helps keep threads intact. Stability reduces the risk of injury and tool damage.

Safety Measures

Using an angle grinder to cut off a bolt can be quick and effective. Safety must be the top priority before starting. Taking the right precautions lowers the risk of injury. Follow these safety measures to protect yourself and those around you.

Eye And Ear Protection

Wear safety goggles to protect your eyes from sparks and debris. Use earplugs or earmuffs to reduce noise from the grinder. Sparks can fly in many directions, so full eye coverage is important. Loud noise can damage your hearing, so protect your ears well.

Hand And Body Safety

Wear thick gloves to protect your hands from sharp metal and hot sparks. Use long sleeves and pants made of sturdy material to shield your skin. Avoid loose clothing that can catch in the grinder. Hold the tool firmly with both hands to keep control.

Proper Workspace Setup

Work in a clean, well-lit area free of flammable materials. Ensure the bolt is securely clamped before cutting to prevent movement. Keep a fire extinguisher nearby in case sparks cause a fire. Clear the workspace of clutter to avoid tripping hazards.

Finishing The Cut

Finishing the cut on a bolt with an angle grinder is a key step. It ensures the bolt remains usable and safe. Proper finishing prevents damage and prepares the bolt for any further use. Take your time to smooth the edges and check the threads. This process improves the bolt’s performance and extends its life.

Deburring The Bolt End

After cutting, the bolt end will have sharp edges. These edges can cause injury or damage. Use a file or flap wheel to remove burrs gently. Hold the bolt steady and work around the cut end. Smooth the surface until no sharp points remain. This step helps tools fit better on the bolt later.

Chasing Threads With Nuts

Cutting may damage the bolt threads near the cut. Fix this by threading a nut onto the bolt. Turn the nut back and forth several times. This action cleans and reshapes the threads. It also removes any small metal pieces stuck in the threads. Chasing threads makes sure nuts will screw on smoothly.

Checking Thread Integrity

Inspect the threads closely after chasing. Look for any bends, cracks, or missing parts. Use a thread gauge if available to check the size. The bolt should hold the nut firmly without slipping. If threads are damaged, the bolt may fail under pressure. Only use bolts with intact threads for safety and reliability.

Credit: www.crcindustries.com

Tips For Small Bolts

Cutting small bolts requires care and precision to avoid damaging the threads or surrounding parts. Using the right tools and techniques makes the process easier and safer. Small bolts often need different handling than larger ones. Simple tools like wire cutters can work well, but they must be used correctly. Protecting the bolt threads is important for reusing the bolt after cutting.

Using Wire Cutters Effectively

Choose wire cutters that are sharp and strong. Position the cutters close to the bolt head for a clean cut. Apply steady pressure without twisting the bolt. Cutting slowly helps avoid crushing the bolt. Keep your hands steady and wear safety glasses. After cutting, check the bolt for sharp edges. Use a file to smooth any rough spots.

Handling Delicate Threads

Delicate threads need protection during cutting. Secure the bolt with a pair of nuts tightened together. This locks the threads and reduces damage. Use a small angle grinder or a fine hacksaw blade for cutting. Cut straight and avoid grinding the threads. After cutting, run a nut along the threads to clean and reshape them. This keeps the bolt usable and extends its life.

Common Mistakes To Avoid

Cutting bolts with an angle grinder is a common task in many projects. Avoiding mistakes can save time and effort. Understanding common errors helps protect your tools and work. Here are key mistakes to avoid when cutting bolts.

Overheating The Bolt

Angle grinders create heat quickly during cutting. Excess heat can weaken the bolt metal. Avoid cutting too long in one spot. Take breaks to let the bolt cool down. Overheating may cause the bolt to lose strength.

Damaging Threads

Cutting too close to the threads can ruin them. Damaged threads make it hard to screw nuts back on. Use two nuts jammed together to protect threads. Cut just below the nuts to keep threads intact. After cutting, clean the threads with a file or nut.

Unsafe Cutting Practices

Angle grinders are powerful and can be dangerous. Always wear safety glasses and gloves. Keep a firm grip on the grinder. Avoid loose clothing that can catch in the tool. Work in a clear, well-lit area to see the bolt properly. Follow all safety instructions for your angle grinder.

Frequently Asked Questions

How To Use An Angle Grinder To Cut Off A Bolt?

Secure the bolt firmly, wear safety gear, and use an angle grinder with a thin cutoff wheel. Cut the bolt carefully, avoiding thread damage. Deburr edges with a file, then run a nut over threads to clean and restore them.

What Is The Best Way To Cut Off Bolts?

Secure the bolt with two jammed nuts. Cut using an angle grinder, oscillating tool, or hacksaw. Deburr edges and run a nut to clean threads. Use wire cutters for small bolts and bandsaws for hard bolts. Always wear safety gear during cutting.

What Kind Of Grinder Wheel To Cut Bolts?

Use a thin cutoff wheel designed for metal on an angle grinder to cut bolts cleanly and quickly.

Can An Angle Grinder Be Used As A Cutoff Tool?

Yes, an angle grinder works well as a cutoff tool. Use a thin cutting disc and wear safety gear. It cuts bolts quickly and efficiently.

Conclusion

Cutting a bolt with an angle grinder is simple and effective. Always wear safety gear for protection. Secure the bolt tightly before cutting to avoid accidents. Use a thin cutting disc for a clean cut. After cutting, remove sharp edges with a file or flap wheel.

Running a nut along the threads can help keep them intact. With the right steps, you can cut bolts quickly and safely. Practice patience and take your time for the best results. This method works well for many DIY and repair tasks.