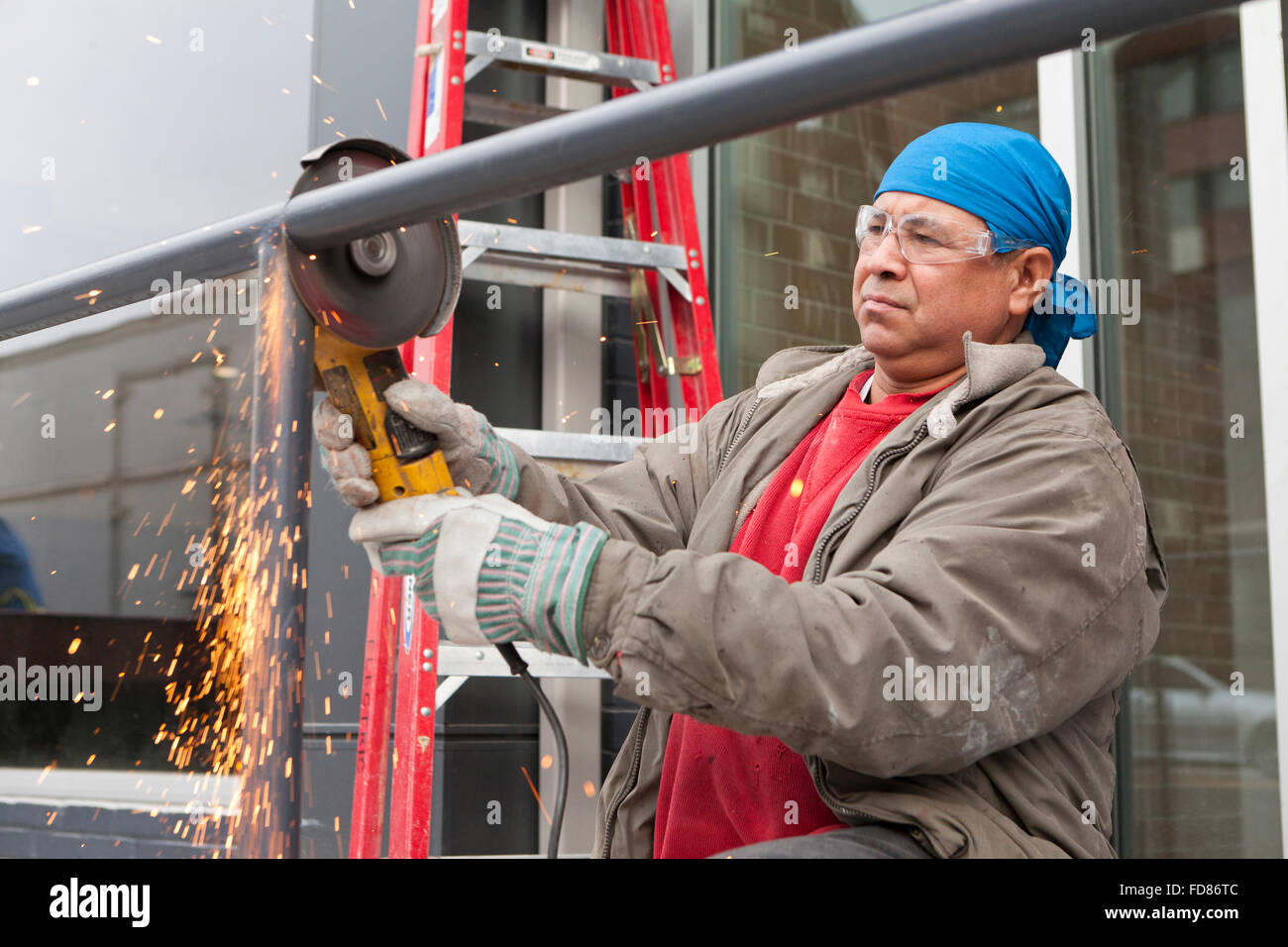

If you’ve ever struggled to get a clean, straight cut on a metal pipe, you know how frustrating it can be. But what if you could achieve perfect pipe cuts with a tool you might already have—your angle grinder?

Cutting pipe with a grinder is not only possible, it can be quick, precise, and surprisingly easy once you know the right techniques. Whether you’re a DIY enthusiast or tackling a professional project, mastering this skill will save you time and improve the quality of your work.

Ready to learn how to make smooth, accurate pipe cuts every time? Let’s dive in and transform the way you handle your pipe cutting tasks.

Credit: www.alamy.com

Choosing The Right Grinder

Choosing the right grinder is essential for cutting pipes efficiently and safely. The proper grinder not only makes the job easier but also ensures clean, accurate cuts. Understanding the types of grinders, the right cutting discs, and necessary safety gear helps you work confidently and effectively.

Types Of Angle Grinders

Angle grinders come in various sizes and power levels. Smaller grinders, like 4.5-inch models, are easy to handle and good for light work. Larger grinders, such as 7-inch or 9-inch, offer more power for heavy-duty cutting. Corded grinders provide consistent power, while cordless models offer portability. Choose a grinder that suits the pipe size and job frequency.

Selecting Cutting Discs

Cutting discs vary by material and thickness. For metal pipes, use discs made for metal cutting. Thin discs cut faster and produce cleaner edges. Avoid using grinding discs for cutting; they are unsafe and damage the pipe. Check the disc’s speed rating to match your grinder’s speed. Always use discs from trusted brands for quality and safety.

Safety Gear Essentials

Safety gear protects you from sparks and debris during cutting. Wear safety goggles to shield your eyes from flying particles. Use ear protection to reduce noise from the grinder. Gloves protect your hands from sharp edges and heat. Long sleeves and pants prevent burns. A dust mask helps avoid inhaling metal dust. Always ensure your safety gear fits well and is in good condition.

Preparing The Pipe

Preparing the pipe is a crucial step before cutting it with a grinder. Proper preparation ensures a clean, straight cut and enhances safety during the process. Taking time to measure, mark, and secure the pipe sets the foundation for a precise cut.

Measuring And Marking

Start by measuring the length of the pipe you need to cut. Use a tape measure for accuracy. Mark the cutting point clearly with a permanent marker or a scriber. Draw a visible line around the pipe’s circumference to guide your cut. Double-check measurements to avoid mistakes.

Using Tape For Straight Cuts

Wrap masking tape or painter’s tape around the pipe at the marked line. The tape acts as a guide and helps prevent the grinder from slipping. It also reduces metal burrs along the cut edge. Align the tape carefully to keep the cut straight and even.

Securing The Pipe

Clamp the pipe firmly to a workbench or use a pipe vise. This prevents movement while cutting and improves safety. Make sure the pipe is stable and won’t roll. A stable pipe allows you to control the grinder easily and make an accurate cut.

Cutting Techniques

Cutting pipe with a grinder requires careful technique to achieve clean, straight cuts. Proper handling improves safety and accuracy. Focus on the right steps to make your work easier and better.

Each part of the cutting process matters, from how you hold the tool to how fast you cut. Avoiding common errors helps prevent damage to the pipe and the grinder disc.

Positioning The Grinder

Hold the grinder firmly with both hands. Position the cutting disc at a right angle to the pipe. Keep the grinder steady and aligned with the marked cutting line. Avoid tilting the disc to prevent uneven cuts.

Maintaining Steady Speed

Start the grinder before touching the pipe. Cut at a consistent speed without forcing the tool. Let the disc do the work. Slow or fast movements can cause rough edges or damage to the pipe.

Avoiding Common Mistakes

Do not rush the cut or apply too much pressure. Avoid cutting without clear markings on the pipe. Check the disc for wear before starting. Keep sparks away from flammable materials. Wear safety gear to protect eyes and hands.

Handling Different Pipe Materials

Cutting pipes with a grinder requires understanding the material you work with. Different pipes need different approaches and tools. Handling pipe materials carefully ensures clean cuts and safety. Below, learn how to cut steel, stainless steel, and galvanized pipes properly.

Cutting Steel Pipes

Steel pipes are common and strong. Use a metal cutting disc on your grinder for best results. Mark the pipe clearly before cutting. Hold the grinder steady and cut slowly. Avoid pushing too hard to prevent disc damage. Wear safety glasses and gloves. Steel can spark, so work in a safe area.

Working With Stainless Steel

Stainless steel is tougher and needs care. Use a disc made for stainless steel or a thin cut-off wheel. Cut slowly to avoid overheating the pipe. Overheating can cause discoloration and weaken the metal. Keep the grinder moving steadily along the line. Use a clamp to hold the pipe steady. Protect yourself from sparks and metal shards.

Dealing With Galvanized Pipes

Galvanized pipes have a zinc coating. Cutting releases toxic fumes. Work outside or in a well-ventilated area. Use a metal cutting disc and cut slowly. Avoid grinding the coating too much to reduce fumes. Wear a mask to protect your lungs. After cutting, clean the edges to prevent rust. Handle galvanized pipes with extra care for safety.

Finishing The Cut

Finishing the cut is a key step after using a grinder to cut pipes. It ensures the pipe edges are safe to handle and fit well in your project. Proper finishing also improves the pipe’s look and function. Neglecting this step can cause injury or poor connections.

Smoothing Edges

After cutting, the pipe edges are often rough. Use a grinding disc or flap wheel to smooth these edges. Move the grinder evenly along the cut edge. This removes sharp points and gives a clean finish. Take your time for an even, smooth surface.

Removing Burrs

Burrs are small, sharp metal fragments left after cutting. Use a wire brush or a deburring tool to remove them. Burrs can cause cuts or block pipe fittings. Clearing them out makes the pipe safer and ready for use. Check all around the cut edge for hidden burrs.

Inspecting The Cut Quality

Inspect the pipe cut carefully before use. Look for straightness and clean edges. Ensure no cracks or uneven spots appear on the cut. A good cut fits better and lasts longer in your project. Fix any flaws by grinding or recutting if needed.

Credit: motionarray.com

Troubleshooting Tips

Troubleshooting is key to smooth pipe cutting with a grinder. Problems can arise during the process, affecting the quality of your cuts and the tool’s performance. Knowing how to handle common issues saves time and ensures better results. Here are some essential tips to fix common problems.

Dealing With Uneven Cuts

Uneven cuts happen when the grinder moves too fast or at the wrong angle. Hold the grinder steady and follow the marked line carefully. Use a guide or clamp to keep the pipe from moving. Take slow, consistent passes instead of forcing the disc through the metal.

Preventing Disc Damage

Disc damage occurs from hitting hard surfaces or using the wrong disc type. Always use discs made for metal cutting. Avoid twisting or bending the disc during use. Replace worn or cracked discs immediately to prevent accidents and poor cuts.

Handling Overheating

Overheating happens when the grinder is used too long without breaks. Stop cutting periodically to let the tool cool down. Use cutting oil or water to reduce heat build-up. Keep the grinder’s vents clear of dust to help with cooling.

Alternative Tools For Pipe Cutting

Cutting pipes requires the right tool for clean and precise results. A grinder is common but not the only option. Different tools fit different needs and pipe types. Exploring alternative tools helps find the best method for your project. Each tool offers unique benefits in ease, speed, and accuracy.

Pipe Cutters

Pipe cutters are simple and effective for many pipe materials. They work best on copper and plastic pipes. The tool clamps around the pipe and tightens as you rotate it. This creates a clean, straight cut without much effort. Pipe cutters are quiet and safe, ideal for small jobs or tight spaces. They do not create sparks or dust, making them suitable indoors.

Reciprocating Saws

Reciprocating saws use a back-and-forth blade to cut through pipes quickly. They handle different pipe materials, including metal and PVC. The saw is powerful and versatile, suitable for rough cuts or demolition work. It can cut pipes in hard-to-reach places. The blade choice affects the cut quality and speed. This tool requires more control to achieve a straight cut.

Portable Band Saws

Portable band saws offer precise and fast cutting for metal pipes. They use a continuous blade that moves in one direction. This results in smooth and even cuts with less effort. Portable band saws are lightweight and easy to handle on job sites. They work well for frequent pipe cutting and larger projects. This tool reduces fatigue and improves cutting accuracy.

Credit: www.youtube.com

Frequently Asked Questions

How To Cut A Pipe Straight With A Grinder?

Mark the cutting line clearly around the pipe. Secure the pipe firmly. Use an angle grinder with a metal cutting disc. Cut slowly along the line, rotating the pipe for an even, straight cut. Keep steady hands and wear safety gear.

What Is The Best Tool For Cutting Pipes?

The best tool for cutting pipes depends on the project. Use a pipe cutter for small jobs. Choose a portable band saw or power tubing cutter for faster, cleaner cuts in frequent or large tasks. An angle grinder also works well for metal pipes with proper safety.

Can You Use A Grinder As A Cutter?

Yes, you can use an angle grinder as a cutter. It cuts metal pipes effectively with a proper cutting disc. Always follow safety precautions and mark the cutting line for accuracy.

How To Cut Metal Pipe Perfectly Straight?

Mark the cutting line clearly around the pipe. Wrap masking tape for guidance. Use an angle grinder with a metal cutting disc. Cut slowly, following the marked line evenly. Rotate the pipe and cut each side to ensure a perfectly straight edge.

Conclusion

Cutting pipe with a grinder can be simple and precise. Always mark your cutting line clearly before starting. Use the right disc and steady hands to follow the line. Keep safety gear on to protect yourself from sparks and debris.

Practice on scrap material to build confidence. With patience, you can achieve clean, straight cuts every time. This skill saves time and effort on many projects. Remember, careful preparation leads to better results.