If you’ve ever needed to cut a steel pipe quickly and precisely, you know it’s not always easy. But here’s the good news: your angle grinder can be the perfect tool to get the job done.

Whether you’re working on a DIY project or tackling a professional task, learning how to cut steel pipe with an angle grinder will save you time, effort, and frustration. In this guide, you’ll discover simple steps, handy tips, and safety tricks to make clean, straight cuts every time.

Keep reading, and you’ll gain the confidence to handle your angle grinder like a pro and get your pipe cutting done right.

Tools And Materials

Cutting steel pipe with an angle grinder requires the right tools and materials. Having proper equipment ensures clean cuts and safe work. This section covers the essential items to prepare before starting your project.

Choosing The Right Angle Grinder

Select an angle grinder with enough power for steel cutting. A grinder with 4.5 to 7 inches disc size works well. Look for one with adjustable speed settings and a comfortable grip. Corded models offer consistent power, while cordless models provide better mobility.

Selecting Cutting Discs

Use cutting discs made specifically for metal. Thin discs provide precise and smooth cuts on steel pipe. Avoid using grinding discs as they are not designed for cutting. Check disc speed ratings to match your grinder’s speed. Replace worn or damaged discs immediately.

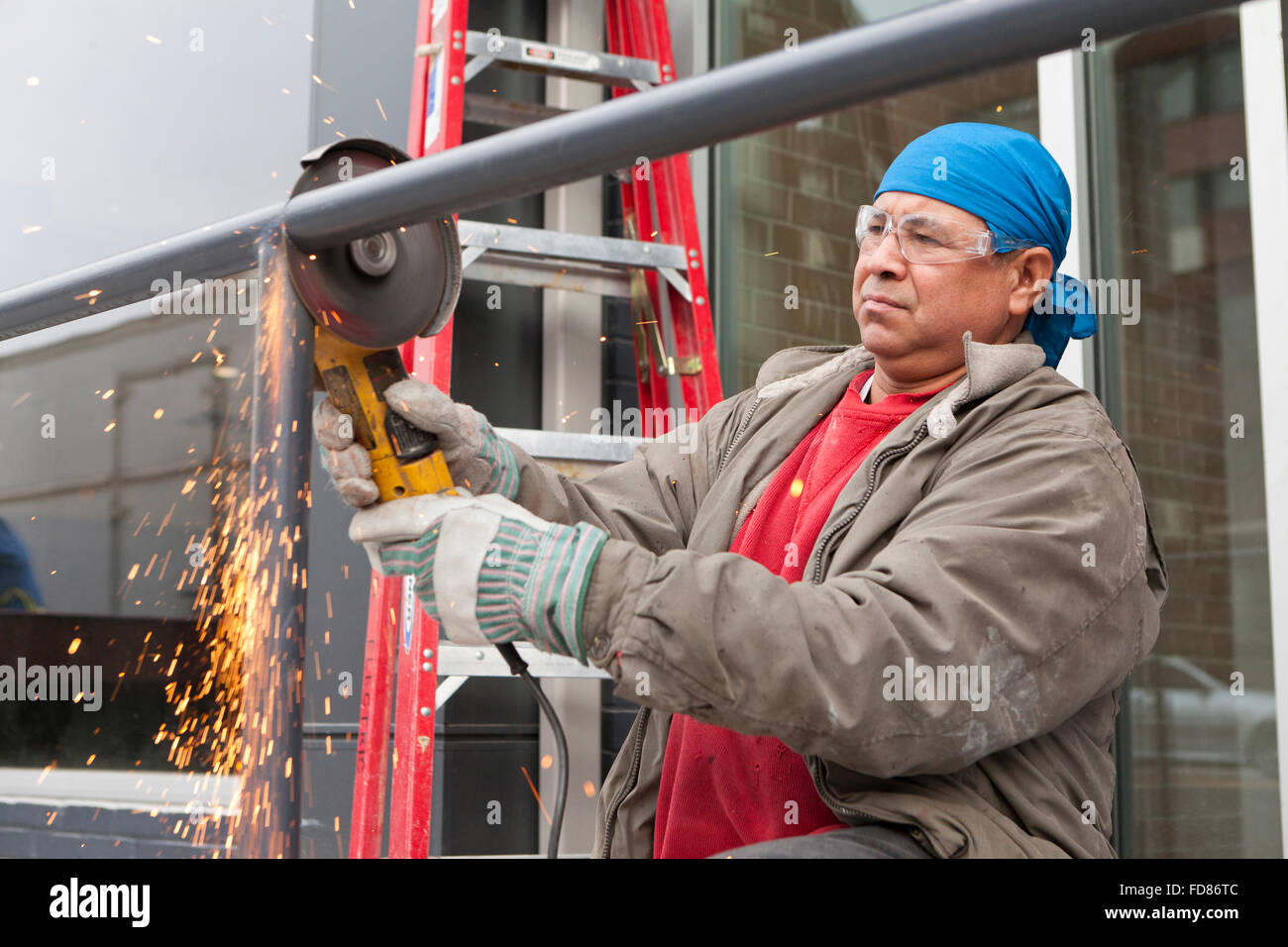

Safety Gear Essentials

Wear safety glasses or a face shield to protect your eyes from sparks and debris. Use ear protection to reduce noise from the grinder. Gloves protect your hands from sharp edges and hot metal. Long sleeves and pants help prevent burns and cuts. Always work in a well-ventilated area.

Credit: www.alamy.com

Preparing The Pipe

Preparing the pipe is the first important step before cutting steel pipe with an angle grinder. It ensures a clean, precise cut and keeps the work safe. Taking the time to properly prepare the pipe saves effort and avoids mistakes during cutting.

Start by measuring and marking the pipe carefully. This guides your cut and helps achieve the desired length. Then, secure the pipe firmly to prevent any movement while cutting. Use clamps or a vise for stability. Finally, apply tape around the pipe to get a straight cutting line. This simple trick improves accuracy and reduces metal burrs.

Measuring And Marking

Use a tape measure to find the exact length needed. Mark the spot clearly with a marker or chalk. Draw a thin, visible line all around the pipe. Check the marking twice to avoid cutting errors. Accurate measurement is key to a perfect fit.

Securing The Pipe

Place the pipe on a sturdy surface. Use a clamp or a vise to hold it tight. Make sure the pipe does not move or wobble. Secure it near the mark but leave enough space for the grinder. Stability prevents accidents and ensures a clean cut.

Using Tape For Straight Cuts

Wrap masking or electrical tape around the pipe at the marked line. The tape acts as a guide for the angle grinder. It helps keep the cut straight and even. The tape also reduces sparks and metal splinters during cutting. This simple step improves the overall finish.

Cutting Techniques

Cutting steel pipe with an angle grinder requires careful techniques to ensure clean and safe cuts. Following proper steps helps avoid mistakes and damage to the pipe or tool. Each step demands attention to detail and steady control.

Mastering these techniques improves the quality of your work and reduces risks. Focus on how to start, position, and apply pressure for the best results. Also, learn how to adjust your approach for different pipe thicknesses.

Starting The Angle Grinder

Hold the angle grinder firmly with both hands. Before touching the pipe, turn on the grinder. Let the disc reach full speed. This prevents the disc from catching or jumping on the pipe. Start cutting only when the tool is stable and steady.

Positioning The Cutting Disc

Align the cutting disc with the mark on the pipe. Keep the disc perpendicular to the pipe surface. This ensures a straight cut and reduces disc wear. Avoid tilting the disc, as it can cause uneven edges or kickback.

Applying Steady Pressure

Push the grinder gently but firmly into the pipe. Use consistent pressure to maintain control. Do not force the disc through the pipe. Let the grinder do the work. Too much pressure can damage the disc or pipe.

Cutting Thick Vs Thin Pipes

For thin pipes, a light touch is enough to cut through cleanly. Cut slowly to prevent bending or warping. Thick pipes need more time and patience. Cut halfway through, then rotate the pipe and finish the cut. Avoid overheating the pipe to keep its shape intact.

Credit: www.youtube.com

Finishing Touches

After cutting steel pipe with an angle grinder, the work is not quite done. Finishing touches improve safety and the pipe’s appearance. They help avoid injuries from sharp edges. This step also ensures the pipe fits perfectly in your project. Taking time for these details makes a big difference.

Smoothing The Cut Edges

Sharp edges can cause cuts and damage. Use a flap disc or sanding attachment on the angle grinder. Gently run it along the cut edges to remove burrs and rough spots. Take care not to remove too much metal. The goal is a smooth, even finish that feels safe to touch.

Checking The Cut Accuracy

Measure the pipe length and angle carefully after cutting. Use a tape measure and square tool to check dimensions. Confirm the cut matches your project needs. If the cut is uneven or off, mark the spot for a small correction. Accurate cuts make assembly easier and cleaner.

Cleaning And Maintenance

Remove metal dust and debris from the pipe and workspace. Wipe the pipe with a cloth or use compressed air. Clean your angle grinder by brushing away dust and checking the disc condition. Proper maintenance extends tool life and keeps cuts precise. Store your tools safely after use.

Common Mistakes To Avoid

Cutting steel pipe with an angle grinder can be simple and effective. Yet, many beginners make errors that cause poor cuts or accidents. Avoiding these mistakes improves your results and keeps you safe. Below are common pitfalls and how to steer clear of them.

Rushing The Cut

Speeding through the cut leads to uneven edges. It can damage the pipe or the disc. Take your time and let the grinder do the work. Slow, steady pressure gives clean, precise cuts. Pausing often helps control the tool and avoid mistakes.

Incorrect Disc Usage

Using the wrong disc harms both the pipe and the grinder. Always pick a disc designed for cutting steel. Avoid discs meant for stone or wood. Check the disc’s size and speed rating. A mismatched disc can break or wear out quickly, risking injury.

Ignoring Safety Precautions

Not wearing safety gear invites serious injury. Always use goggles, gloves, and hearing protection. Secure the pipe firmly before cutting. Keep your hands clear of the disc path. Work in a clean, well-lit space to spot hazards early.

Tips For Efficient Cutting

Cutting steel pipe with an angle grinder needs care and skill. Simple techniques help you cut faster and cleaner. Follow these tips to improve your cutting work.

These tips also make your work safer and extend the life of your tools. Small changes bring big results in your cutting process.

Using Guides And Jigs

Guides and jigs keep your angle grinder steady. They help you cut straight lines every time. Using a guide reduces mistakes and saves material.

You can buy ready-made guides or make one from wood or metal. Clamp the guide firmly to the pipe before cutting.

Maintaining Disc Speed

Keep the disc speed steady for clean cuts. Too slow makes rough edges. Too fast wears out the disc quickly.

Check the grinder’s settings before starting. Let the grinder reach full speed before touching the pipe. This gives smooth and even cuts.

Working In Well-ventilated Areas

Cutting steel pipes creates dust and fumes. Work outside or in a place with good airflow. This protects your lungs and keeps the workspace safe.

Use a mask and safety glasses for extra protection. Keep fire hazards away since sparks fly during cutting.

Credit: www.simplifiedbuilding.com

Frequently Asked Questions

Can An Angle Grinder Cut Metal Pipe?

Yes, an angle grinder can cut metal pipes effectively. Use a cutting disc, steady pressure, and safety gear for precise, clean cuts.

What Is The Best Tool To Cut Steel Pipe?

The best tool to cut steel pipe is an angle grinder with a metal cutting disc. It offers speed, precision, and versatility. Battery-powered pipe cutters also provide clean, straight cuts for smaller pipes. Use steady pressure and mark the cut line for accuracy.

Can You Cut Through Steel With An Angle Grinder?

Yes, an angle grinder can cut through steel quickly and precisely. Use a proper cutting disc and steady pressure for best results.

How To Cut A Pipe Straight With An Angle Grinder?

Mark the cut line with masking tape for guidance. Start the angle grinder before touching the pipe. Lower the disc slowly and apply steady pressure. Rotate the pipe to cut evenly around its circumference. Finish by smoothing edges with a file or sandpaper.

Conclusion

Cutting steel pipe with an angle grinder is simple and effective. Always wear safety gear for protection. Mark the pipe clearly before starting your cut. Use steady, controlled movements to ensure a clean cut. Keep the grinder steady and avoid forcing the tool.

Practice on scrap pieces to build confidence and skill. Following these steps helps you cut pipes quickly and safely. This method suits many DIY projects and professional tasks. With care and focus, you can achieve precise, smooth cuts every time.